Professionals in the livestock market

Our specialists advise professional livestock enclosure builders with regard to the smartest possible layout of drinking water facilities. The type of piping systems, the number of drinking troughs per herd and the choice of materials: They devise the most suitable solution for any circumstances. Customisation is the key.

Best-selling products

Product groups

We can help realise your project

Markets

About livestock

Livestock specialists

Our livestock specialists immerse themselves in the sector. Short lines of communication with our customers ensure that they always know what is going on.

By acquiring the greatest possible range of specialist market knowledge, they can invariably come up with sustainable solutions.

Creating added value

Our specialists endeavour to go the extra mile for Bosta’s customers. While they much prefer to visit customers on site, they keep in close contact by phone or email in cases where that is not possible.

They view every situation as unique. They make sure that they stay abreast of developments and trends in the livestock sector. They adapt their advice accordingly and remain involved afterwards. “Every livestock enclosure is unique, and therefore so are its water requirements.”

Mission and vision

Our mission? To keep close track of the constantly changing livestock market and new legislation, and to directly apply it to the customer’s circumstances.

“As water becomes increasingly scarce, targeted watering is more important than ever. By advising customers about smart water solutions in their livestock enclosures, we contribute to a world where water is used efficiently.”

Frequently asked questions

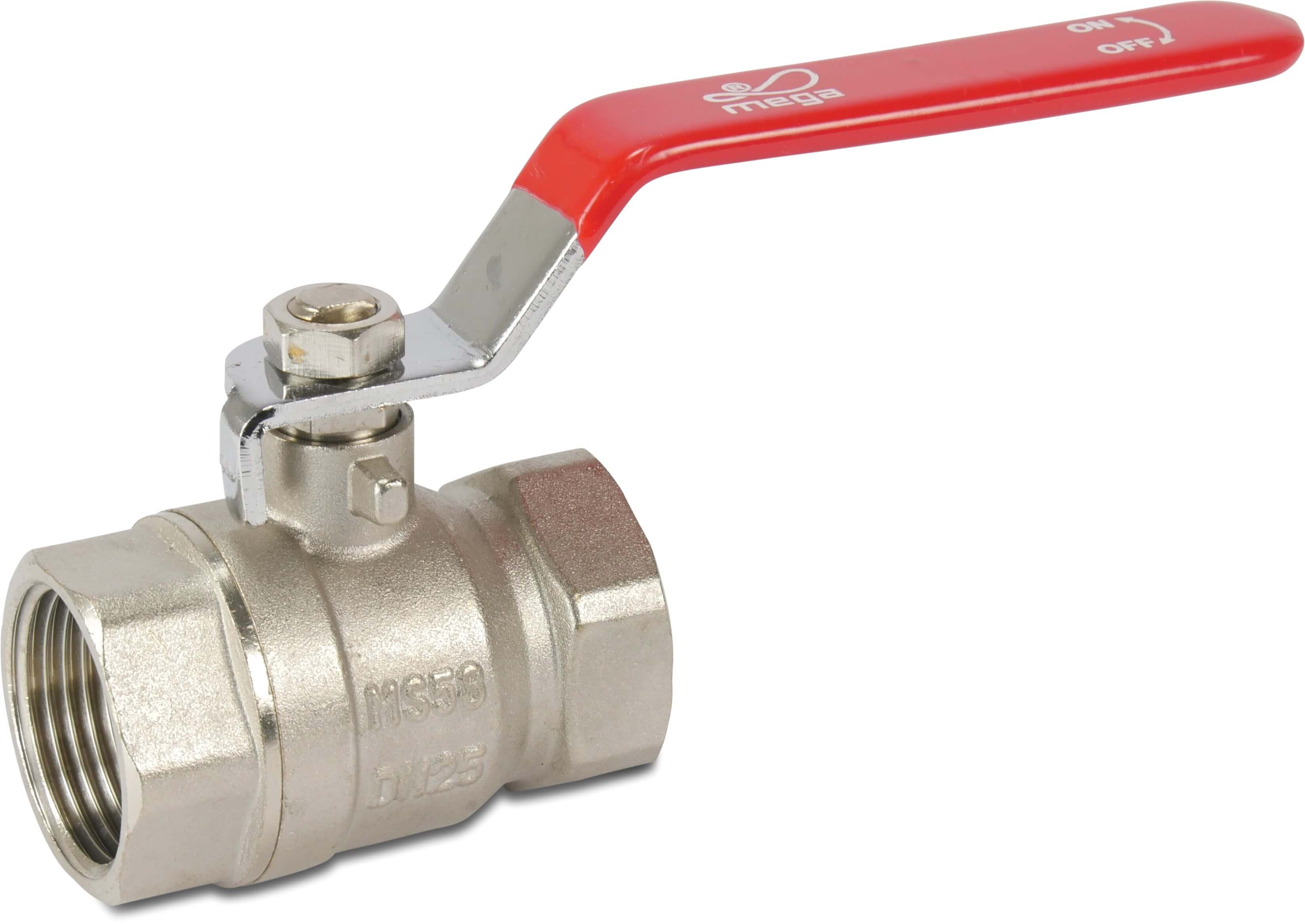

What are the standards used for pipe fittings?

The standards may varies between manufacturers but currently the fittings in our assortment may be confirmed to BSP, BPT, NPT and DIN standards.

What are the factors considered while selecting a pipe and its fittings?

The main factors on which a design and selection of a pipe fittings are pipe material, size of pipe, operating temperature, required pressure rating.

How are pipe fittings identified?

Pipe fittings are generally by material, inner and outer diameter of the pipe and the type of connection viz. glue socket, compression fitting, hosetail fitting, male or female thread etc.

What are the applications of reducer fittings?

Reducer pipe fittings are mainly used for changing diameter of pipelines, to handle the damages which may arise due to misalignment, vibration, and thermal expansion.

How are pipe fittings generally categorised by male and female connectors?

Male threaded fittings: External threads which made to screw into the inside portion of a larger diameter pipe end with internal threading.

Female threaded fittings: Internal threads which are made to receive male threaded pipe fittings.

Male Spigot fit: No threads on the surface but can be slipped into a slightly larger female socket fit and can be joined with the aid of suitable adhesives.

Female Socket fit: No threads on the surface but can be made to receive a narrower male spigot fit and can be joined with the aid of suitable adhesives

What is a galvanised steel pipe?

Galvanised steel pipes are steel pipe coated with a protective layer of zinc, which serve sacrificial layer for protecting the pipe from rust and corrosion. Galvanisation coating is generally performed by either hot dipping or cold galvanisation process steel pipe.

Frequently asked questions

The standards may varies between manufacturers but currently the fittings in our assortment may be confirmed to BSP, BPT, NPT and DIN standards.

The main factors on which a design and selection of a pipe fittings are pipe material, size of pipe, operating temperature, required pressure rating.

Pipe fittings are generally by material, inner and outer diameter of the pipe and the type of connection viz. glue socket, compression fitting, hosetail fitting, male or female thread etc.

Reducer pipe fittings are mainly used for changing diameter of pipelines, to handle the damages which may arise due to misalignment, vibration, and thermal expansion.

Male threaded fittings: External threads which made to screw into the inside portion of a larger diameter pipe end with internal threading.

Female threaded fittings: Internal threads which are made to receive male threaded pipe fittings.

Male Spigot fit: No threads on the surface but can be slipped into a slightly larger female socket fit and can be joined with the aid of suitable adhesives.

Female Socket fit: No threads on the surface but can be made to receive a narrower male spigot fit and can be joined with the aid of suitable adhesives

Galvanised steel pipes are steel pipe coated with a protective layer of zinc, which serve sacrificial layer for protecting the pipe from rust and corrosion. Galvanisation coating is generally performed by either hot dipping or cold galvanisation process steel pipe.